07 Jan 2019

If you work with your hands, your workbench is often your best friend and most reliable tool of your trade. Whether you’re in warehousing, heavy industry, mining, or just a DIY enthusiast, you’ll be using a workbench a lot. So which workbench is right for your workplace? What will give you the best workflow, and prevent injuries such as RSI or muscular damage? Here’s a guide to what’s on the market, and what workbenches will suit your environment and your work requirements.

First Things – Measurements

Before selecting workbenches, you need to figure out the dimensions of your workbench space, and if it has enough clearance for the types of materials or machinery you work on, and enough space for thoroughfare. Safety is the rule when selecting a workbench – so keep it at the top of your list when looking for benches.

Fixed vs Height Adjustable Workbenches

One of the major trends in occupational health and safety is height adjustable workbenches. These can be configured for “standing” modes and adjusted back down to “desk” mode, in which you sit at the bench as normal. Standing while working does have its health benefits. Even so, a height adjustable bench will suit many more employees, giving them the option to switch positions on the fly, to make sure the height is ergonomic and comfortable. Height adjustable workbenches can also improve efficiency, as workers walking from one station to the next need not have to stop and sit down to attend to their duties.

Pictured: Electric Height Adjustable Workbench

Mobile or Stationary – Consider Your Needs

Sometimes a mobile workbench on castors is relevant to the modern workplace, especially if a workbench has specialised equipment housed on it. It can be repositioned into the part of the floor that needs the tools, computers, etc. Some mobile workbenches feature handles for easy manoeuvrability. For a highly compartmentalised workspace, a stationary workbench (or many benches) may be what your business needs.

Pictured: Stainless Steel Mobile Workbenches

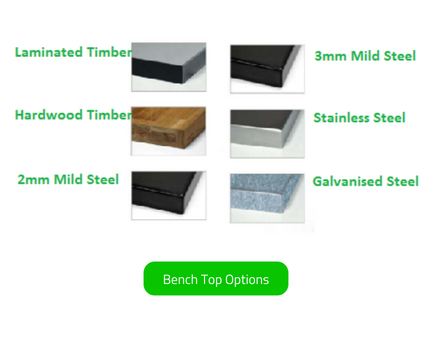

Worktop Materials to Suit your Environment

There are many options for worktop materials to help prolong the lifespan and improve the durability of your workbench. For example, the most affordable and most compatible worktop material is a simple hardened board. It’s good for light workshop environments. Up in the durability factor is laminate, which gives a smooth and scratch-resistant surface for all-round dependability. Just like steel benches, it’s liquid and chemical resistant, lasts a long time, and is easy to clean.

Vinyl benchtops are softer to the touch yet retain high friction to prevent slips. This is good for workplaces that can’t risk damaging the items they’re working on such as in packing or assembly work. Oak Parquet is a a stronger and more durable solid wood benchtop that also suits assembly work, as well as metal machining.

Pictured: Heavy Duty Modular Workbench

Workbenches with Extra Storage

Many workbenches come with storage options for tools, personal effects, packing materials, and other items. These may be in the form of shelves, lockers, or cable trays, giving workers easy access to crucial work materials.

If you want the best range of workbenches for your workshop, contact Backsafe for more information on our range of reliable and ergonomic workbenches.

Back To News Stories